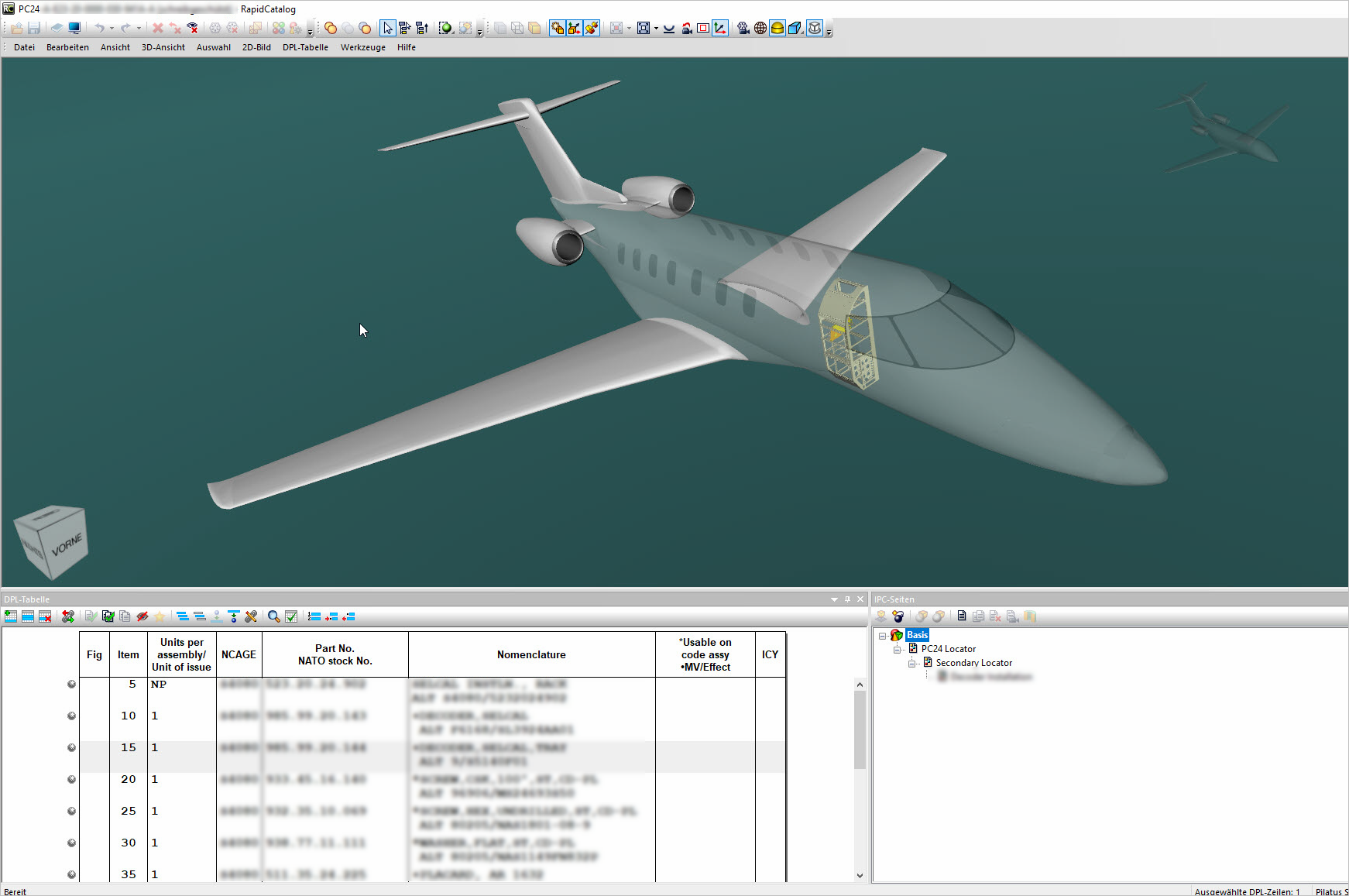

Pilatus PC-24 will receive 3D interactive parts catalogs and instructions

Pilatus PC-24 will receive 3D interactive parts catalogs and instructions for continued airworthiness

Pilatus is a Swiss company that develops, produces, and sells aircraft to customers around the world. The latest aircraft is the PC-24 – the world’s first-ever business jet for use on short unprepared runways.

PC-24 has a special support program, CrystalCare, designed to complement customers, leasing companies, and aircraft financiers and provide the most comprehensive service. Production of interactive Illustrated Parts Data (IPD) and Structural Repair Manual (SRM) is part of this program.

The Technical Publications department decided to go digital, clear format of documentation, that facilitates the maintenance of the plane. Another goal was to increase the efficiency of the authoring process. To achieve this the company introduced considerable changes to the existing system environment: PLM – tech pubs’ authoring software – CSDB. The results are quite impressive: significant reduction of production time and positive feedback from the service centers regarding new documentation.

The challenge

The software that was previously used for technical publication production has reached the end of its lifecycle and required quite intensive maintenance.

Production of 2D technical documentation was a two-phase process – compiling followed by illustrating. Technical writers and illustrators were working in different environments largely isolated from the PLM system.

There was also a business need to introduce new technologies that will help to streamline the authoring process and add new capabilities such as interactive 3D to the documentation.

Why Cortona3D

Pilatus selected Cortona3D as it provides a solution fully integrated with Teamcenter PLM which enables Pilatus to optimize the Parts Catalog production process. RapidAuthor for Teamcenter from Cortona3D enables Parts Catalog compilers to work in the PLM environment, interact directly with engineering and product data, and rapidly create and update 3D interactive technical publications.

Other strong points of Cortona3D include powerful customization capabilities, fast and professional technical support, and regular updates of the software.

We work with RapidAuthor every day, so it’s not so obvious, but the tool is very well connected. We can take information that we need out of Teamcenter and set it up properly before we export our data model to the next system in case we need a revision or make changes.

Sebastian HaakeICT Application Engineer, Pilatus

Implementation: key goals and tasks

The main project goal was to get an effective system for the production of interactive 3D IPD and SRM parts identification in accordance with S1000D standards.

To achieve this goal Pilatus needed several tasks to be completed:

- Integration of RapidAuthor with the Pilatus business processes defined in the Teamcenter Product Data Management system.

- Integration of RapidAuthor with the HiCo S1000D Common Source Data Base.

- The transition from 2D to 3D documentation authoring.

- Customization of the software in accordance with specific Pilatus requirements.

The RapidAuthor software is easy to use and really friendly. Typically, when you are going to switch to new software you may confront the users with new technology and the users who work with the old tool, like 2D-oriented technical publications. I don’t remember having these problems using RapidAuthor. We are always looking to be faster, better quality, and easy to handle. We talk a lot with our business, IT, and our technical partners to find out a better solution together and discuss how we can be better in our daily work.

Cristopher Alcaide AmreinTeam Leader Technical ICT, Pilatus

Customized functionality

The implementation project included the continuous exchange of ideas between Pilatus and its partners which resulted in the creation of new time-saving features among other improvements. A few highlights are provided below.

Book is the place in Teamcenter to put IPD and SRM data modules to manage them together. It allows the authors not to lose time by searching the information in Teamcenter and helps to minimize errors.

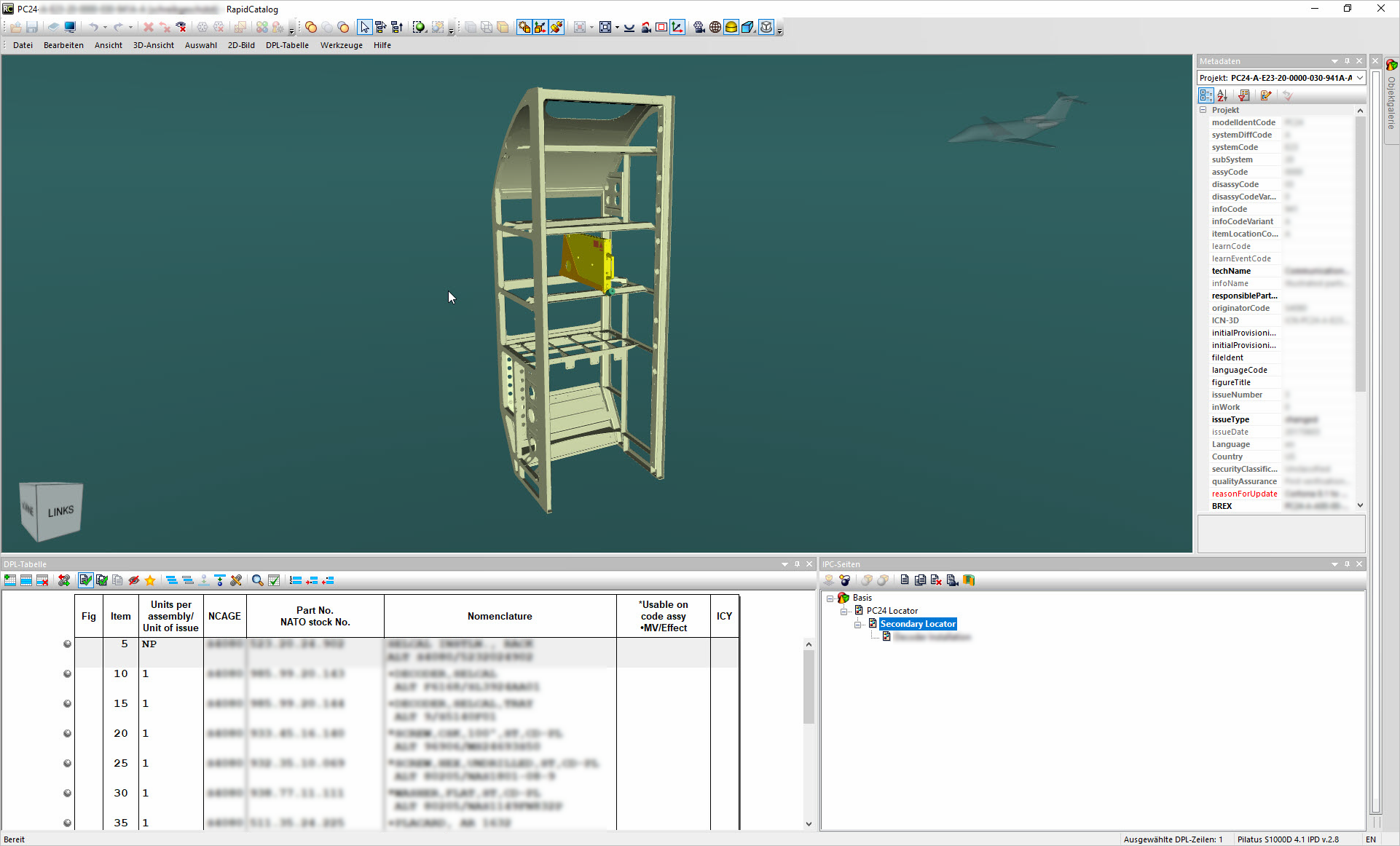

This is RapidAuthor Update Wizard with extended configuration tailored to Pilatus business processes. Mapping engineering and PLM data directly with the text and 2D/3D graphics allow authors to easily compare a compilation with its previous version, identify changes, and update documentation.

Authors do not have to search for all changes manually and this saves a lot of time. They can also easily trace the links back to the source data to verify the information in the data module, which makes the documentation more accurate and ensures that there is no outdated or wrong information inside.

Authors can see what they change. They can identify really quickly which parts are new and which parts are old. We didn’t have such a tool before.

Cristopher Alcaide AmreinTeam Leader Technical ICT, Pilatus

Automated metadata entry into data modules (e.g., revision) is based on the relationships between a data module and the product structure. It allows Pilatus to import the information created in the legacy software and keep using this data module instead of creating a brand new one.

The information that some parts should be replaced by others is very important for the authors because they have to display it in the documentation and make sure that there are no mistakes there. RapidAuthor can read this information from Teamcenter: if an existing item should be replaced by a new one, a DPL row for the new item will be automatically generated underneath the existing item. As a result, compilers don’t have to go through the information in Teamcenter to review it, and they don’t have to manually create the DPL row and enter all related data. It saves a lot of time.

The customization process has both advantages and disadvantages. Being able to introduce software enhancements that benefit our ever-changing processes is a big plus. Of course, if one customizes something, one can face problems, and these can be difficult to identify. For every system update, functional enhancement, or fix for a software bug we want to implement, we must ensure that the change does not negatively affect the software or a connecting software. Therefore, we meticulously test our software, while collaborating closely with Siemens, Cortona3D, and HiCo. This ensures the successful implementation of an enhancement.

Sebastian HaakeICT Application Engineer, Pilatus

Results and benefits

Now Pilatus has a single production environment for the 3D IPD and SRM encompassing both, compiling and illustrating. Authors have one environment to work with 2D, 3D, text, and animation, there is no need to switch between different tools. The tech pubs team can use CAD and PLM data directly from Teamcenter improving the quality and accuracy of documentation while spending fewer resources.

Development time of the 3D IPD and SRM was cut by an estimated 40% due to the simultaneous capability of compiling and illustrating and enhanced functionality. Software customization has brought its results too: it has reduced production time and increased efficiency by approximately 30%.

The in-depth Teamcenter integration and ability to update DPL tables with RapidAuthor has also increased the efficiency of the compilation process for traditional 2D IPD, reduced the costs of compilation, and improved the compilation user interface.

3D documentation: positive feedback from the service centers

Created technical publications are available on MyPilatus Customer Portal and on Supplier Portal. The feedback from the service centers is positive: 3D interactive documentation is easy to handle for workshop employees. They don’t waste time searching for the required information page after page in large paper manuals, all information is available on iPad. Digitalization is making the service and maintenance of aircraft easier and faster.

We believe that the 3D IPD has been greatly received and the transition of the normal IPD production within the Cortona3D environment was not negatively commented after initial rounds of discussion.

John WintersManager Technical Publications, Pilatus

Plans for the future

Every new model of the plane that will come to the market will receive 3D parts catalogs and interactive service manuals. Besides iPad, Windows solution is planned to view 3D parts catalogs.

A piece of advice from the Pilatus Tech Pubs team for someone looking for innovations

Every time you look for innovation and you try to implement something new, keep it as simple as possible. Try to understand the software. Evaluate its efficiency and time-to-money. Going for a new technology you have to take into account the necessity of integration of your legacy data. Talk internally and externally regarding the idea, figure out missing points and find the answers to them. Let your employees submit ideas for further improvement.

Thank you note

We thank the project team for sharing their experience with us.

The Pilatus project became special for us. It pushed the development of the Cortona3D product in terms of the S1000D technical publication standard forward. We learned a lot from our customers. And it’s one of the best ways to develop the product when you can work directly with people who use the software for their business. Pilatus has a great team eager to develop and implement new technologies. We had powerful support from the Pilatus side and developed a trusting, win-win relationship with people.

Ruslan AytkulovProject Manager, Cortona3D

Siemens, Cortona3D, and HiCo are really open to working together. It was nice to work with them and we got all support we need. They are great partners for our company.

Cristopher Alcaide AmreinTeam Leader Technical ICT, Pilatus

Founded in 1939, Pilatus Aircraft Ltd is the only Swiss company to develop, produce and sell aircraft to customers around the world. Domiciled in Stans, the company is certified to ISO 14001 in recognition of its efforts for the environment. The Pilatus Group includes two independent subsidiaries in Broomfield (Colorado, USA) and Adelaide (Australia).

- RapidAuthor

- Teamcenter

- Make the service and maintenance of the aircraft faster and easier

- Reduce time and cost for the tech pubs' production

- Creating 3D-enabled documentation instead of traditional 2D

- Use of highly integrated solution

- High-quality support from the software vendors

- Development time of the 3D IPD and SRM was cut by 40%

- The efficiency of the authoring process increased approximately by 30%

- Positive feedback of service centers for 3D documentation

- Pilatus Aircraft Ltd

- Cortona3D

- HiCo